Environmental Product Declarations (EPDs) are not just the hot new thing in the construction industry. They’re becoming a critical component and metric for the industry during the design process to determine which materials make the most sense for the build—particularly in an increasingly stringent regulatory environment.

EPDs provide verified details on the environmental impact of a product throughout its entire life cycle, from raw materials to disposal. This means architects, engineers, and contractors (AEC) can make informed decisions about the materials they use in construction projects and ensure they’re making the most sustainable choices for the environment and the people who occupy the building.

Let’s face it, the construction industry has a bit of a reputation for being a major contributor to the global carbon footprint. Buildings are responsible for around 40% of energy consumption and 36% of greenhouse gas emissions worldwide. The good news is that EPDs can help change that by informing the industry of the environmental impact of their material choices, prior to specifying them.

EPDs are based on Life Cycle Assessment (LCA) methodologies, which considers the entire life cycle of a product, from raw materials to disposal. This means an EPD will provide verified information about the energy used to extract and transport raw materials, the energy used in production, the emissions produced during manufacturing and even the energy used in transportation to the building site. It also includes information on the end-of-life scenarios, such as recycling, incineration or landfilling. This comprehensive approach allows the AEC industry to make informed decisions about the environmental impact based on the lifecycle of materials, rather than just considering the environmental impact of one stage of the product’s life.

EPDs are also becoming more important as building codes and regulations are becoming more stringent. Many countries and regions have introduced regulations that require new buildings to have pre-determined levels of energy efficiency. Some even have regulations requiring the use of materials with low environmental impact. EPDs can help the AEC industry comply with these regulations by providing them with the information they need to select materials that meet the required standards.

On top of that, EPDs also help in the selection of products that can contribute to certifications such as LEED, BREEAM, and WELL, that are becoming more and more popular among building owners, developers, and tenants.

When looking at an Environmental Product Declaration (EPD), builders should look for the following details:

- Life Cycle Assessment (LCA) Methodology: The EPD should be based on an LCA methodology, which takes into account the entire life cycle of the product, from raw materials to disposal. This will provide a comprehensive view of the environmental impact of the product.

- Environmental Impact Categories: The EPD should provide information on the environmental impact of the product in several categories, such as energy consumption, greenhouse gas emissions, water usage, and waste generation. This will allow builders to evaluate the product’s impact on several different environmental aspects.

- Data Sources: The EPD should provide information on the data sources used to generate the environmental impact data. This will allow builders to evaluate the credibility and reliability of the data.

- Comparison with Similar Products: The EPD should provide information on how the product compares to similar products in the market. This will allow builders to compare the environmental impact of different options and make an informed decision.

- End-of-Life Scenario: The EPD should provide information on the end-of-life scenarios for the product, such as recycling, incineration or landfilling. This will give builders an idea of the product’s impact on the environment after it has reached the end of its useful life.

- Certifications: EPDs should also provide information on certifications, such as LEED, BREEAM and WELL and how the product would contribute to these.

- Contact information: The EPD should provide contact information for the organization that developed the EPD, including a website and email address. This will allow builders open communication with the organization if they have any questions or concerns about the EPD.

These indicators communicate transparent and comparable information about the life-cycle environmental impact of products, allowing builders to make informed decisions for the products they specify. Having an EPD for a product does not imply that the declared product is environmentally superior to alternatives—it is simply a transparent declaration of the life-cycle environmental impact.

It is possible for companies to fake Environmental Product Declarations (EPDs), or present false or misleading information about the environmental impact of their products. However, there are several ways to ensure that an EPD is reliable and trustworthy.

- EPDs are typically developed by third-party organizations that are accredited by international organizations such as the International EPD System, and follow the ISO 14025 and EN 15804 standards. These organizations are responsible for verifying the data provided by the company and ensuring that the EPD is accurate and reliable.

- EPDs are also verified and validated by the International EPD System or other accreditation bodies, and they will be issued with a unique EPD registration number.

- EPDs can be compared with industry averages and benchmarks, to ensure that the data presented is reasonable.

The best approach is to check for the EPD’s registration number, the accreditation body and the standard it has been developed under, and compare with industry averages and benchmarks, to ensure that the information provided is reliable. Additionally, it is always recommended to consult with the EPD’s developer if you have any doubts or questions.

Essentially, EPDs give you the big picture. They’re like the nutrition label on food products—only for building materials. They give us all the information we need to make informed decisions about the materials we build with and help us create more sustainable and energy-efficient buildings for the people who occupy them.

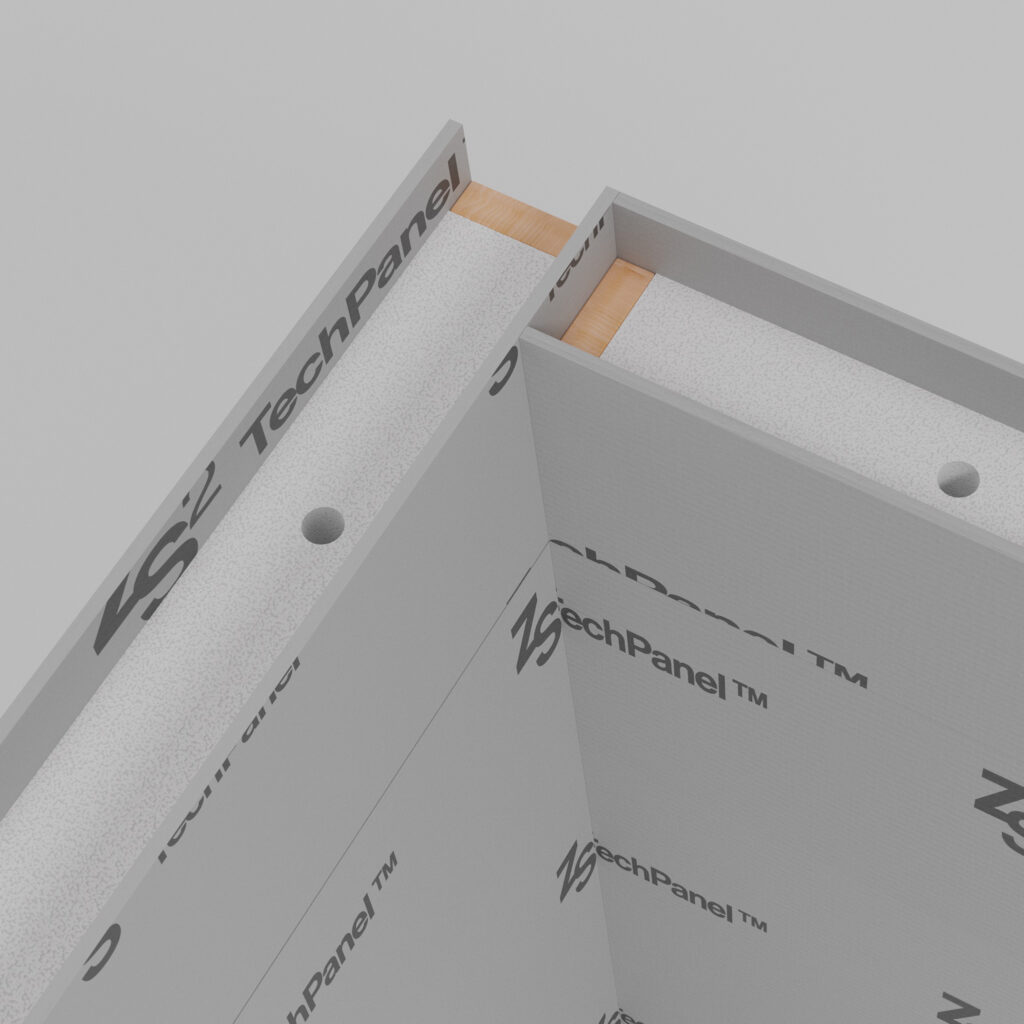

If you’re looking to take a more conscious approach to building, be sure to look for a thorough EPD. In the meantime, check out the announcement for the most recent verified EPD for ZS2 TechPanels.

ZS2 Technologies achieves 70% reduction in carbon footprint after full Lifecycle Analysis

ZS2 Technologies, Canada’s leading sustainable building materials developer and manufacturer, achieved an Environmental Products Declaration with a 70 per cent reduction in CO2 when compared to traditional construction.